Baosteel Group Company Limited and Wuhan Iron and Steel (Group) Company Limited (WISCO) were jointly reorganized in September 2016. The merged China Baowu Steel Group Corporation (hereinafter referred to as "China Baowu") is the most modern and competitive iron and steel joint enterprise in China, and also a super-large modern iron and steel joint enterprise in the world. China Baowu continues to promote intelligent manufacturing and digital transformation, and proposes four evaluation criteria for intelligent manufacturing process of iron and steel: centralized on-site operation rooms, robot operation posts, remote O&M monitoring, and online service procedures. Under a unified industrial Internet architecture, China Baowu is committed to promoting the three-cross integration, that is cross-industry, cross-space, and cross-man-machine interfaces.

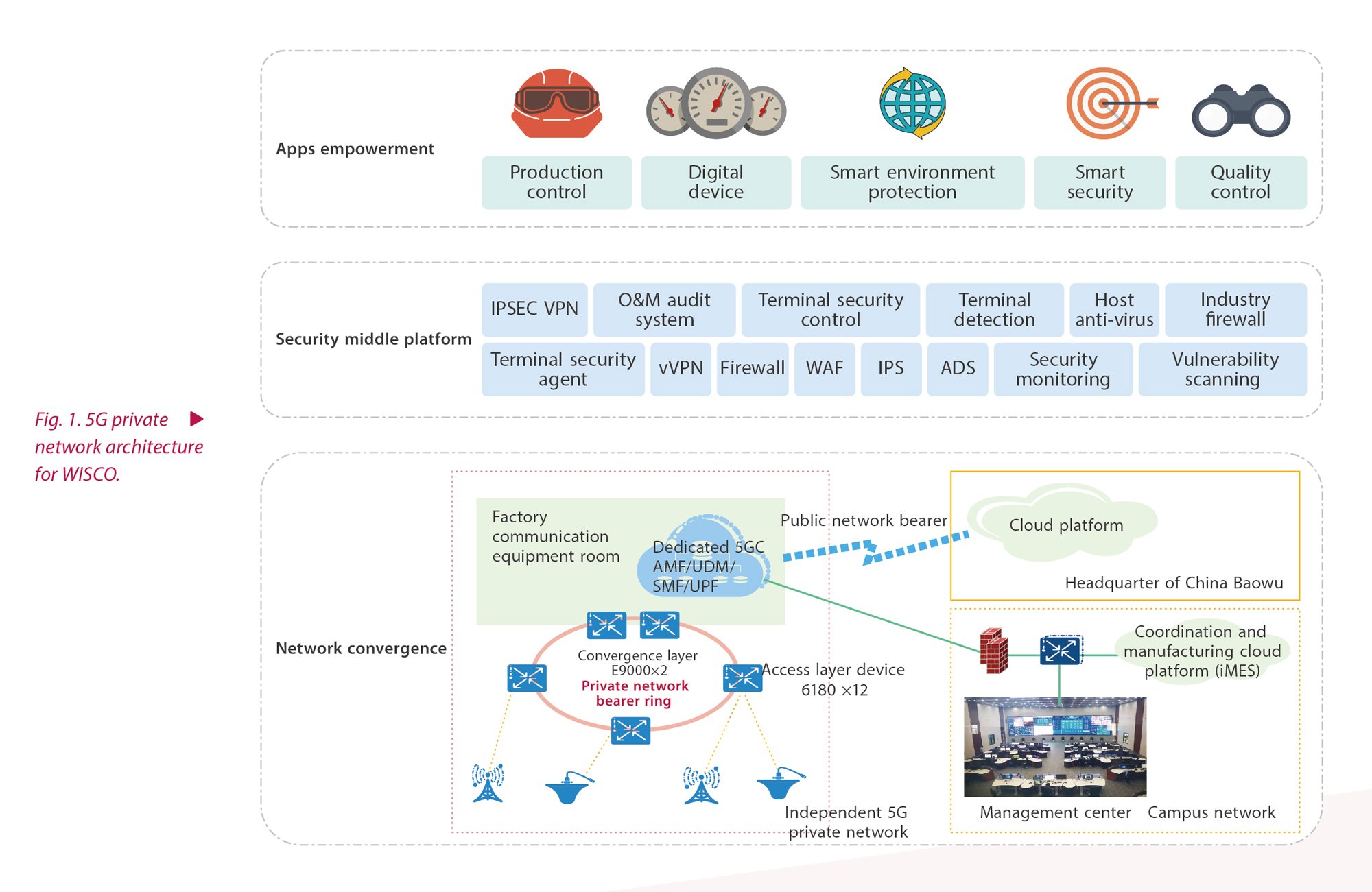

WISCO encountered some challenges in promoting digital transformation. Its existing siloed information system made it difficult to exchange information between systems, and its communication networks could not have sufficient coverage and were not scalable enough to meet the requirements of smart manufacturing. To meet the requirements of four evaluation criteria and three-cross integration, WISCO introduced the 5G private network technology to leverage 5G advantages such as low latency, large bandwidth, and wide connections to achieve digital transformation. In the first half of 2021, Hubei Unicom joined hands with ZTE and CISDI to build the 5G private network project of WISCO. According to the requirements of intelligent manufacturing business and the characteristics of the iron and steel industry, Hubei Unicom chose independent private network mode to build the largest 5G private network in China for WISCO (Fig. 1).

WISCO's 5G private network is exclusively provided by ZTE. The whole core network is offloaded and the complete set of 5GC NEs are deployed in the communication equipment room of the factory, which provide 5G data services for private users (using private network cards) and support value-added services such as private network voice/SMS as needed. Based on the network function virtualization (NFV) architecture, the 5G private network adopts the general X86 server and networking mode in accordance with the CT resource pool standard, and provides separation of control, computing and storage, so as to meet the needs of service growth through hardware expansion and software upgrade. It also adopts mature 3GPP R15 specifications of the industry, provides good terminal and network compatibility, and supports the continuous evolution to the latest R16/R17 version. Through software upgrade, it supports innovative features such as 5G LAN, QoS monitoring, and TSN, and continuously empowers smart manufacturing.

A total of 51 5G macro sites have been set up and commissioned in WISCO's 5G private network. Its outdoor coverage tested reaches 99.02%, with an average downlink throughput of 800.59 Mbps and an average uplink throughput of 150.78 Mbps.

The entire 5G network is independently operated by WISCO, and all security policy rights are fully controlled, achieving the highest level of security, control and management. The 5G private network is highly independent from the public network on the physical transmission layer. There is no need to backhaul data and signaling flows in the campus to the public network. The campus network is totally isolated from the public network, guaranteeing data security in the campus. WISCO is the first to implement the concept of "ALL IN ONE" smart manufacturing. It has built the management and control center and four major operation centers for iron making, steel making, CSP and hot rolling. Its operation rooms are centralized and far away from the site, making the functions such as data integration, real-time collection, one-click steel making and smart transportation a reality. With the gradual maturity of terminal products of the R16 standard and the rapid development of various innovative technologies such as 5G LAN, TSN, digital twin and XR, various applications will also be put into use on a large scale.

The project of "Baosteel 5G+ full-connection factory's innovative application and practice" jointly built by Hubei Unicom, WISCO, ZTE and CISDI won the first prize in the fourth "Bloom Cup" 5G Application Contest in China. Together with WISCO and Hubei Unicom, ZTE will continue to explore 5G+ industrial Internet, practice 5G+ innovative applications, and comprehensively assist the digital and intelligent transformation of the iron and steel industry.