Mobile OAM Improves On-Site OAM Efficiency and Quality

On-site OAM encompasses base station patrols; fault repair; emergency power generation; line inspection; optical fiber cable welding; and installation, removal, relocation, and maintenance of fixed-line broadband. Traditional on-site OAM is low-tech, labor-intensive, and focused on network resources. It determines overall network stability and customer experience; therefore, the quality of on-site OAM is vital to an operator. Because on-site OAM is so important in increasingly complex networks, operators are spending more and more on opex. In the 4G era, changes in network architecture and service models have created many new challenges for on-site OAM. What is the current status of on-site OAM and how should we handle these new challenges?

On-Site OAM: Status and Challenges

There are currently two OAM models: self-maintenance and OAM hosting. Both have the following problems:

● extensive personnel management. On-site OAM is labor-intensive, sometimes involving a large number of OAM personnel who are dispersed and have varying technical skills. It can be difficult to supervise and assess the performance of on-site OAM personnel.

● hard-to-regulate OAM process. Management personnel often fail to monitor on-site OAM processes, keep up with the progress of numerous work orders in real time, or guarantee that tasks are completed on time.

● poor asset management. On-site OAM involves numerous objects of different types. It is easy to lose track of spare parts and materials, and this makes it more difficult to manage assets and expenditure.

● shortage of efficient OAM tools. Traditional OAM lacks unified tools. Work order dispatching is recorded manually and reported via phone calls and SMS. Thus, reporting may be time consuming, and statistics may be outdated.

ZTE Launches Mobile OAM

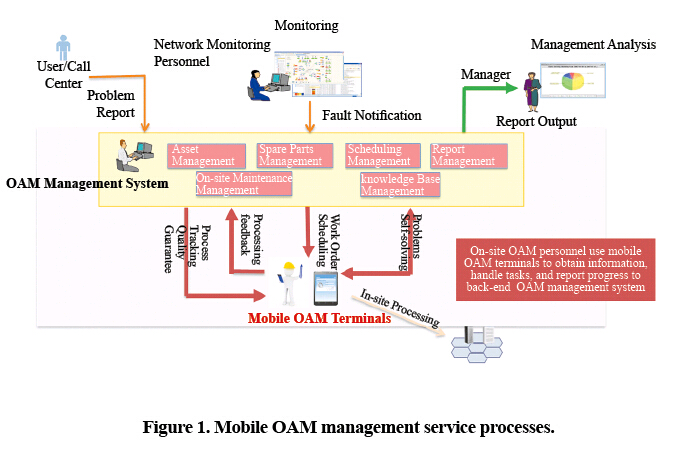

The mobile internet has brought to users various new services and experiences. Will its openness inspire network OAM? ZTE has introduced mobile internet to OAM by developing mobile OAM app tools that can be used to solve on-site OAM problems. ZTE analyzed traditional on-site OAM and consulted operators about their specific OAM needs. ZTE then deployed an OAM system and mobile app that can be used together to change organizational structure, improve work process, and optimize human resources (Fig. 1). The mobile OAM service helps operators improve on-site OAM, reduce OAM costs, boost OAM efficiency and quality, and increase user satisfaction.

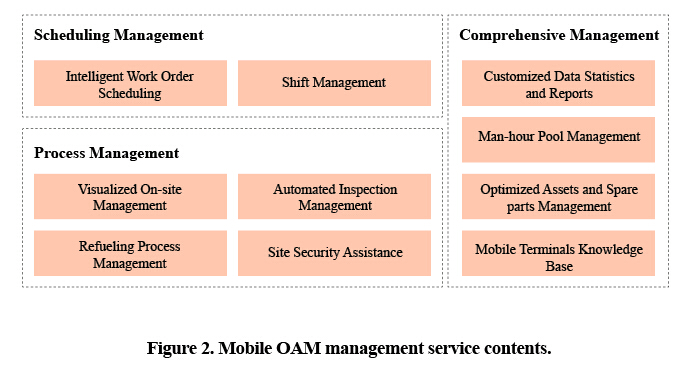

On-site OAM personnel can use mobile OAM terminals to handle tasks online, obtain information, and report progress anytime, anywhere. Personnel can schedule tasks, manage other personnel, control quality, and report statistics using the mobile OAM system. By analyzing data across the entire OAM process, personnel can also locate weak points and continuously improve quality and efficiency (Fig. 2).

Scheduling Management: Improving Task Scheduling Efficiency

Work orders are automatically associated with the SLA in order to meet deadlines. There are a number of different ways of scheduling work orders. For example, work orders can be dispatched to the nearest OAM personnel to optimize scheduling and improve efficiency. Shift management also guarantees seamless handover, clear responsibility, and continuous work.

Process Management: Ensuring Task Execution Quality

Visualized on-site management involves on-site OAM personnel using mobile OAM terminals to report on-site handling progress in real time. Scheduling managers can then obtain on-site information in a timely manner.

Automated inspection management is guided inspection management. Inspection personnel follow the requirements specified in the work orders on their mobile terminals and complete tasks. In addition, the inspection processes are recorded on mobile OAM terminals without the need for any paperwork.

Refueling process management involves determining the fuel capacity and oil consumption of oil engines, manage the refueling process, and controlling related costs.

Site security personnel can use mobile OAM terminals while on patrol to increase site security.

Comprehensive Management for Continuous Improvement

Data statistics and reports can be customized. The data generated during OAM is recorded through mobile OAM terminals. Data analysis helps OAM teams improve KPIs, optimize OAM processes, close network vulnerabilities, and optimally allocate human resources.

The routine activities of OAM personnel are also recorded on mobile terminals. This data can be used to analyze performance, create effective assessment systems, and bolster enthusiasm and efficiency.

All assets and spare parts are managed electronically. Asset lifecycle management is supported. Bar code and QR code systems make managing assets and spare parts easier.

On-site maintenance personnel have round-the-clock access to a knowledge base so that they can handle difficult problems by themselves. This reduces dependence on back-end technical support.

Mobile OAM Management Service Improves On-Site OAM Quality and Efficiency

Improving On-Site OAM Management

Mobile OAM enables end-to-end electronic processing of on-site OAM as well as end-to-end tracking of fault work orders. In addition, it integrates the geographic information system (GIS) to visualize the OAM personnel’s locations and status. The photographing and dotting function of mobile OAM terminals enables the maintenance process and results transparent. The bar code and QR code systems increase data entry query efficiency and accuracy.

Enhancing OAM Personnel Efficiency

On-site OAM personnel can access the OAM system through mobile terminals anytime, anywhere to handle OAM tasks. Application of terminal OAM experience and knowledge base lowers the skill requirements of maintenance personnel and reduces the need for back-end technical support. Man-hour pool management is introduced to build an effective assessment mechanism and increase work efficiency. Graphical and multi-strategy scheduling enables flexible responses to emergency situations or multitasks to enhance staff scheduling efficiency.

Increasing Assets and Material Utilization

OAM assets are electronically managed so that they can be used optimally. With the assets OAM life cycle management, OAM personnel can be reminded to remove or replace relevant assets before expiration.

Optimizing OAM Process

By analyzing network performance indicators, fault work orders, assets, spare parts, and statistical data of OAM process, OAM teams can improve KPIs and optimize OAM process.

In the mobile internet era, operators have been creating new OAM models that integrate network maintenance management and local maintenance support. Centralized network monitoring enables the network management center to dispatch work orders to on-site OAM personnel when a fault occurs. This speeds up the troubleshooting response. The mobile OAM management service complements the intensive OAM system in on-site OAM. Mobile OAM strengthens OAM transformation and local maintenance support.