OTDR+GIS-Based Intelligent Fiber Fault Location System

Problems

Fibers are the core carrier of optical transport network (OTN). Since OTN networks carry a huge number of services, fiber cuts have a considerable impact on the services, and the repair efficiency directly affects user experience.

Some of the reasons for fiber cuts include engineering construction, rainstorms, and road deformation due to truck weight. When a fiber cut occurs, the OTN system reports the alarm to the maintenance personnel. After determining it is a fiber cut, the maintenance personnel will go to the equipment room at either end of the broken fiber, use the OTDR to measure the distance to the fault, locate the fault based on the analysis of the measurement results and the fiber inventory information, and go to find the break point and repair it.

This traditional mode has serious disadvantages in both timeliness and efficiency. The untimely fault location and insufficient location accuracy make it difficult for the maintenance personnel to repair the fiber.

Solution

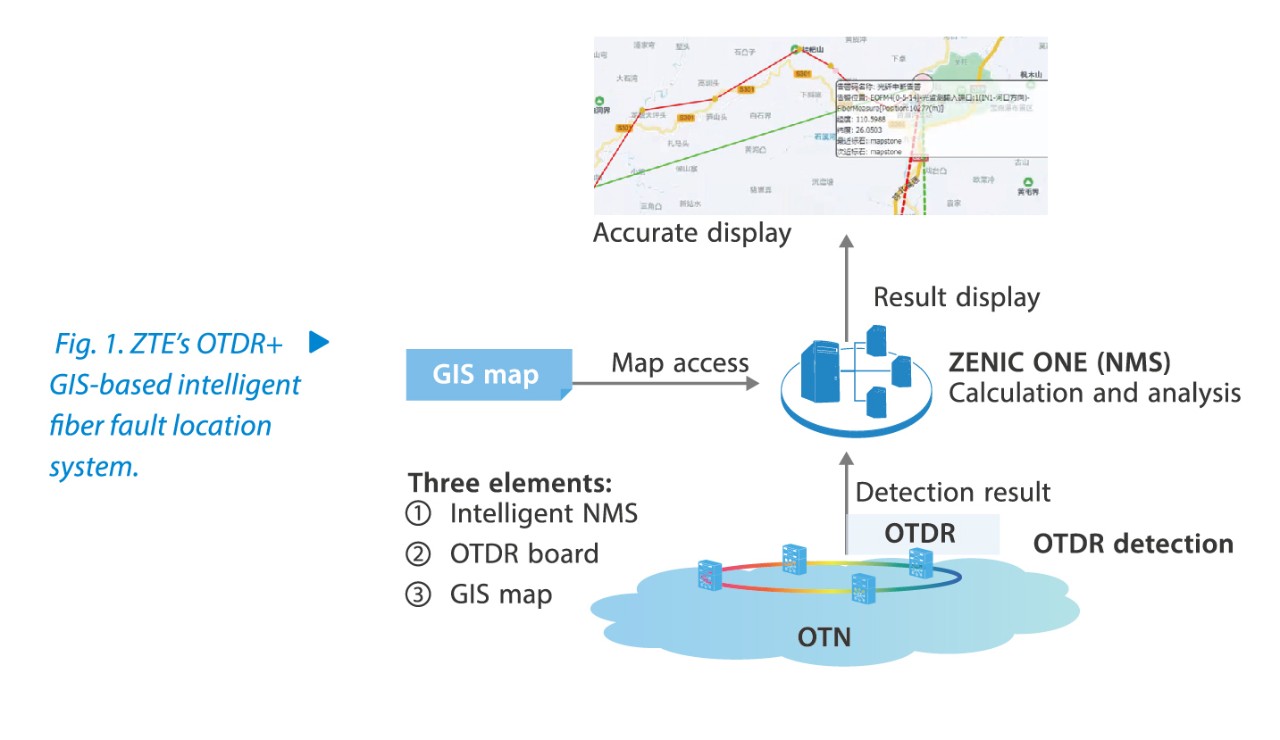

To automatically locate fiber fault and increase the repair efficiency, we have developed the OTDR+GIS-based intelligent fiber fault location system. The system includes three major elements: intelligent network management system (NMS), OTDR board, and GIS map (Fig. 1). The OTDR detects the distance to the fault point. The intelligent NMS as the core and brain of the whole solution calculates and analyzes alarms and data and gives a visual representation of the fault location on a map.

When a fiber fault occurs, the system operation procedure is as follows:

—Alarm detection and analysis: Fiber cuts will cause the loss of OTN line signals. The intelligent NMS can detect the alarms in real time. A fiber fault will cause faults with all service layers and services that pass these layers. In this case, a large number of alarms will be reported, and the system does not know whether it is a fiber fault, laser fault, or board fault at the beginning. The intelligent NMS prompts the maintenance personnel through audio and visual alarms. Based on AI and the library of rules, it analyzes the correlation between different alarms to determine the root cause (fiber cut).

—OTDR detection: After determining that it is a fiber fault, the NMS immediately triggers the OTDR to detect the faulty fiber link. The OTDR board measures the distance from the site where the OTDR board is located to the fault point through the use of scattered or back reflected light.

—Intelligent analysis and result display: The distance detected by the OTDR is not the longitude and latitude nor a specific location on the map, and cannot effectively guide the maintenance personnel. The intelligent NMS is needed here. With the AI-based intelligent analysis, the ZENIC ONE obtains the latitude and longitude of the fiber fault location based on the test results and OTN topology information as well as the information about the fiber cables, markstones, and length of compensating fiber. Finally, the NMS graphically displays the fiber fault location with the GIS map.

—Fault repair: The external maintenance personnel can clearly see the accurate location of the fault point, go there quickly and repair the fault.

It can be seen that the intelligent NMS allows the maintenance personnel to quickly learn about the specific location of the break point and go to repair it quickly, thus ensuring the stability of the OTN network.

Benefits

The intelligent fiber fault location system effectively solves the problems of O&M timeliness and efficiency, and improves the location efficiency by more than 90%. When a fiber fault occurs, the system can immediately find out the exact fault location (in longitude and latitude) and displays it on the GIS map visually. In this way, it leaves out the process of manual analysis, fault judgment and fiber information query, improving the location efficiency and saving the maintenance costs. Take a municipal branch of an operator as an example. Before the intelligent fiber fault location system is deployed, it takes the maintenance personnel at the network management center about

10 minutes to analyze and determine the fault. Then they notify the external maintenance personnel to go to the corresponding equipment room. It takes the external maintenance personnel an average of 40 minutes to arrive at the equipment room and about 10 minutes to complete the test and analyze the approximate location of the fiber fault, and about one hour is needed to complete the overall fault location process. After the intelligent fiber fault location system is deployed, the fault analysis can be completed within five minutes after a fault occurs. The system automatically analyzes the specific location of the break point and notifies the maintenance personnel. The whole location process is shortened by about 55 minutes and the location efficiency is improved by more than 90%. The external maintenance personnel can directly go to the fault point instead of the equipment room for testing, thereby shortening the repair time. At the same time, a large amount of O&M expenses such as vehicle use, test instrument maintenance and depreciation can be saved.

Conclusion

The OTDR board is similar to a common service board and can be installed in any common slot. With the addition of the network management software package and GIS map data, the network can implement the intelligent fiber fault location function without being directly modified. Therefore, this system function can be rapidly copied and deployed in other OTN networks. The wide application of this function can accelerate the recovery of line faults, improve network robustness, reduce O&M costs, and help operators provide better service experience for users.