Building Green FTTx Network for Sustainable Future

The global temperature has been rising at an average rate of 0.08°C per decade since 1880, making climate change a pressing concern for humankind. Against this backdrop, it is inevitable for enterprises and industries to seek sustainable development through adopting green practices. The ITU forecasted that by 2030, the carbon emissions in the ICT industry would decrease by around 45% compared to the 2020 levels. For fixed-network operators, achieving green growth involves efforts on five fronts:

—Accelerating the adoption of green energy and transforming the paradigm of energy use.

—Adopting new processes, new solutions, and new designs to reduce the power consumption of equipment.

—Planning networks in a holistic manner to boost energy efficiency.

—Strengthening automatic and intelligent energy consumption management to improve energy conservation.

—Disposing of disused facilities in a way that maximizes resource reuse.

As a leading player in the telecommunications industry, ZTE is able to contribute to these efforts by employing green technologies, building green central offices (COs), deploying green networks, implementing green production and transportation, and following green practices throughout the product lifecycle.

Green Technologies Improve Energy Efficiency

ZTE actively assists operators in fiber transformation by building future-proof fiber to the x (FTTx) networks with energy-efficient, fiber-based passive optical network (PON) technology. FTTx is significantly more environmentally friendly compared with copper access networks. Take the digital subscriber line (DSL) as an example, which is a copper access technology. FTTx emits only one fifth of greenhouse gases and consumes just one third of power of DSL. Fiber as a material is also more sustainable than copper. Production of one kilometer of copper generates 10.8 kilograms of carbon dioxide, while the same output of fiber has a carbon footprint of just 3.07 kilograms. Moreover, fiber enjoys a longer lifecylce than copper. In contrast to copper technology, FTTx can increase energy efficiency by 60 times.

As PON technology evolves, FTTx networks will become faster, more reliable, incur lower OpEx, and produce less carbon emissions.

Green COs Lay the Foundation of Energy Efficiency

ZTE constantly develops new processes, solutions and designs around PON technology. The resulting innovations reduce energy consumption at the chip, card and equipment levels, enabling operators to build green COs.

—At the chip level: ZTE's optical line terminals (OLTs) are equipped with in-house 5-in-1 chips whose integration level is twice that of the industry average. Because of the higher the integration level, the lower the power consumption per unit volume, each Combo PON port of the OLTs consumes 32.7% less power than the Code of Conduct on Energy Consumption of Broadband Equipment Version 7.0 (CoC V7).

—At the card level: The Combo PON and Any-PON cards of OLTs can be deployed flexibly. The Combo PON card, which carries innovative 3-in-1 Combo PON optical modules, reduces line card types by 67% and does not introduce additional power loss. Upgrading GPON to 10G PON with the Combo PON card saves 60% space compared with upgrading schemes that use an external optical multiplexer. The Any-PON card integrates five access technologies, enabling technological upgrades by just swapping the optical modules in the card without replacing the card itself. In other words, by simply replacing the optical modules of the Any-PON card, operators can implement multiple access modes like GPON, XG(S)-PON and Combo PON, thereby saving 80% line card types and avoiding a waste of resources caused by card replacement.

—At the equipment level: Small-capacity OLTs make network deployment more flexible and are suitable for deployment in far-flung and sparsely populated areas, new buildings in cities, and fixed-mobile convergence (FMC) scenarios. In these places, large-capacity OLTs may cause a waste of resources and capital because a large number of their slots may be left idle. Another benefit of a small-size OLT is low power consumption. For example, a 2U OLT consumes 59% less power than a large-capacity one, and a 1U OLT slashes power consumption by 76% as compared with a large-capacity one. The carbon emissions reduction produced by a 2U OLT and a 1U OLT each year is equivalent to the amount of carbon absorbed by 76,000 and 183,000 trees, respectively.

Green Networks Reduce Energy Waste

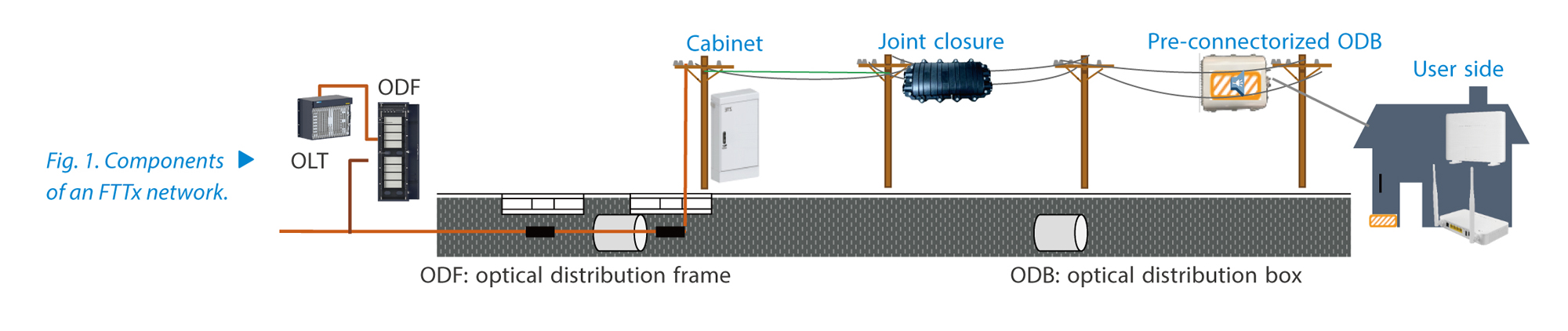

ZTE plans networks in a holistic manner, paying attention to all levels of deployment from COs to the whole network to increase energy efficiency (Fig. 1).

—ODNs: ZTE uses EU RoHS 2-compliant environmentally-friendly materials to construct optical distribution networks (ODNs). Its eMonitor solution can implement automatic preventive maintenance of ODNs, accurately locate faults, and guide engineers in troubleshooting. As a result, operators can reduce the energy consumed to manually check the network and locate faults. Moreover, ZTE ODNs use fully pre-connectorized products that do not need hot soldering on-site, thus avoiding the wear and tear caused by plugging and unplugging, improving termination efficiency by 80%, and saving 50% deployment time.

—ONUs:

ZTE's optical network units (ONUs) feature well-rounded energy-efficient designs. The in-house ONU chips also constantly evolve. The chip design has gone through several development stages from separation of GPON MAC and 10G PON MAC to full-mode MAC and then to programmable full-mode MAC. Consequently, the power consumption of ZTE GPON ONUs is currently 20% lower than the CoC V7 standard.

Green Delivery Enhances Overall Energy Efficiency of Network Projects

ZTE's smart factory uses an industry-leading intelligent packaging line for subracks. The line automates the whole process of subrack packaging to save labor and production costs. The factory also uses automatic conveying equipment to improve the efficiency of material distribution by 30%. The cutting-edge sorting system of the factory boosts operation efficiency by 220% over traditional sorting methods.

A digital supply chain is also established. ZTE uses a combination of data and algorithms to drive the digital twinning of its supply chain, which in turn realizes real-time sensing and smart decision-making and enables the best solutions to be produced and efficiently implemented. ZTE's visualized, perceptive and adjustable intelligent operation center allows big orders to be rapidly processed and the delivery period to be shortened. Working with the world's top logistics service providers, ZTE has built an agile global logistics network that includes 14 international transfer hubs, 31 domestic provincial-level warehouses and 7,400-plus global freight routes. Its intelligent early-warning system for risks enables dynamic selection of transport solutions and reduces the environmental impact of delivery.

Green Product Lifecycle Management Controls Waste Disposal and Strengthens Resource Reuse

ZTE analyzes, evaluates and manages the lifecycle of its products, which ranges from product design at the beginning to waste recycling at the end, in strict accordance with the ISO 14040 standard for environmental impact assessment. It practices the principle of 3 Rs—reduce, reuse and recycle—throughout the product lifecycle to minimize the environmental footprint of products.

—Reduce: ZTE complies with the EU's RoHS 2 standard and has established an environment management system based on the IECQ QC 080000 specification to minimize the hazardous substances used in its products. By using more environmentally-friendly materials and modernizing production techniques, ZTE cuts the volatile organic compounds emitted throughout the lifecycle of its products by more than 90%. In 2012, ZTE eliminated the use of halogen-based flame retardants in its products. In production and operations, it practices lean management and constantly upgrades its manufacturing process to conserve resources and energy.

—Reuse: ZTE adopts green packaging and modular product designs to maximize the reuse of materials. More than 70% of ZTE's cabinets are packed in cartons. 100% of package printing for ZTE products uses plant-based ink instead of petroleum-based ink. 100% of ZTE products are modular and platform-based to facilitate maintenance and reuse.

—Recycle: ZTE products adopt a recyclable design that allows scrapped products to be easily disassembled, reused and classified and different materials to be easily separated. ZTE has joined forces with environmental service providers to build a global green recycling network. In addition, it provides operators with one-stop equipment recycling services including disassembly, recycling and disposal.

ZTE is committed to environmental protection and actively promotes sustainable development to create value for customers.