5G Private Network Solution for Open-Pit Mines: Promoting Large-Scale Application of Unmanned Mining Trucks

Open-pit mines include open-pit coal mines and hillside stone mines. In an open-pit coal mine, the surface soil is stripped off to form a huge mine with a depth of ten to hundreds of meters. The coal seams buried at the bottom of the pit are dug up and transported to the coal storage area. In a hillside stone mine, stone materials are excavated from top to bottom and transported to the unloading area at the foot of the hill. In recent years, the open-pit mining industry has proposed an intelligent development goal of "safety, fewer people and unmanned coal mining", and there is an urgent need to reduce costs and increase efficiency. With mature applications of new technologies such as machine vision, self-driving, remote control and 5G wireless communication, open-pit mining is rapidly evolving to intelligence. As the connection infrastructure of intelligent mobile equipment, the 5G private network has been widely used in the core production domain of mines.

Intelligent Open-pit Mining Creates Need for Wireless Communications

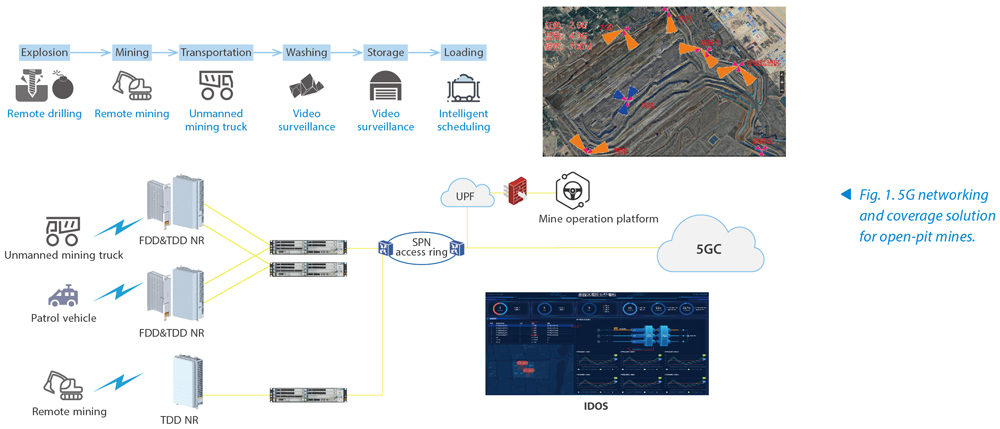

Open-pit coal mining involves explosion, loading, and transportation. In the process of intelligent transformation, new services are introduced such as unmanned mining truck transportation, remote control of electric shovel, auxiliary equipment monitoring, and intelligent vehicle management and control. Wired optical cables cannot meet the mobility requirements of mining trucks, which has created the need for 5G wireless networks.

An open-pit mine covers a wide area, ranging from two square kilometers to dozens of square kilometers. The core working surface is slowly advanced, gradually getting away from the coverage area of base stations. Therefore, it is necessary to swap and redeploy some base stations. There are dozens to hundreds of unmanned mining trucks, electric shovels, excavators, earth-moving trucks, and other heavy equipment in the open-pit mine, which imposes high requirements on the uplink capacity of the network and the low latency and high reliability of remote control instruction transmission.

Open-pit mines have high requirements for production safety and reliability. When there are tasks for high productivity, 24-hour production is required and network failures will greatly affect mining efficiency and operation benefits.

5G Networking and Coverage Solution for Open-Pit Mines

Generally, in small-and-medium-sized open-pit mines, a hybrid 5G private network is used to construct an independent UPF resource pool in the mining area for disaster recovery and ensuring that production data does not go out of the mines. The public network and private network share 5G new radios (NRs), and traffic is logically isolated through the slicing technology. Physical resource blocks (PRBs) are deployed to reserve high-priority air interface resources for private network services. In a large open-pit mine, security requirements are extremely high. In general, an independent private network solution is deployed to provide the highest security, in which base stations and the core network are exclusively used and physically isolated from the public network.

Considering the distinct environments and requirements of each functional area, the planning of the open-pit mine network needs to be tailored to individual areas. In a mine or a large-scale operation platform where overlapping coverage and co-channel interference are serious, SuperCell is needed to avoid frequent handover and co-channel interference. On the transportation road, line coverage is needed to reduce cell handover and ensure service experience of continuous driving. In living areas and coal washing areas, full coverage is needed to make a large number of terminals connected.

For the scenario where the working surface of an open-pit mine moves slowly, ZTE has developed trailer-type movable base stations that integrate the antenna, baseband and mast.

The antenna can move upwards and downwards, as high as 18 meters, and has strong wind resistance capability. The movable base stations are flexible and can quickly complete swap and network recovery.

5G Enhanced Technologies Ensure Continuous High-Intensity Operations of Core Production Business in Complex Open-Pit Mine Scenarios

The FDD+TDD dual-band network uses different features of FDD and TDD to complement each other in coverage to meet the changing mine environment. When the unmanned mining truck is moving, it can be connected to an appropriate frequency through the inter-frequency interoperability policy to achieve dynamic load balancing.

The dual-frequency networking also improves network availability, preventing single-frequency network faults from affecting production business.

For core production business such as unmanned mining trucks and remote electric shovel, frame replication and elimination for reliability (FRER) is used to transmit control instructions. The sender replicates multiple copies of a data frame that needs to be transmitted, generates a sequence number, and then transmits the data frame on a disjoint redundancy network path. At the destination, the copies are checked according to the sequence number of the data frame, and the duplicate ones are discarded. In this way, seamless redundancy transmission is implemented, and low-latency high-reliability guarantee is provided. When the mining truck needs to be taken over remotely due to a fault in self-driving, the video backhaul delay and picture quality can affect the driving experience. ZTE's industry-leading ultra-low latency video transmission technology reduces the end-to-end delay from about 300 ms to less than 80 ms. Its video technologies such as error correction and packet loss prevention can ensure smooth high-definition pictures and improve remote driving experience.

To meet the uplink large capacity requirements of unmanned mining trucks and remote electric shovels in open-pit mines, SuperMIMO is used in SuperCell networking to enhance the uplink capacity. Four distributed 8T8R RRUs are deployed to form a 32T32R multi-antenna system. In the MIMO system, multiple nodes send and receive signals in a unified manner. On the premise of ensuring continuous self-driving of unmanned mining trucks, the uplink capacity can be increased to ensure smooth backhaul of multi-channel videos.

The intelligence digital operational service (IDOS) for open-pit mine scenarios manages 5G terminals, NRs, UPFs, core network, and production businesses, and presents end to end the status and performance indicators of each node of service flow links. By setting guarantee requirements, quality monitoring, and problem identification, demarcation and location, a closed-loop SLA guarantee is built to make the 5G private network better serve production operations of the open-pit mine.

5G Private Network Continues to Empower Intelligent Transformation of Open-Pit Mines

ZTE has assisted China's operators in deploying 5G private network solutions in several open-pit mines in Xinjiang, Inner Mongolia, Shaanxi, and Anhui, which have passed commercial acceptance. In some projects, the mining trucks allow security personnel to get off the trucks, truly achieving unmanned operations—self-driving. With the growth of open-pit mining businesses such as unmanned mining trucks and remote electric shovels, 5G private network will continue to enhance the intelligence of open-pit mines.