5G+ Industrial Internet: Creating a New Era of Fully-Connected Factories

Since 2020, the global deployment of 5G networks has been initiated. At present, there are more than three million 5G base stations built worldwide. Moreover, 5G networks have been widely adopted and implemented in important industries.

The industrial Internet is the central component among various elements in the application of 5G in factories. It directly serves the IT and OT business systems of enterprises, while the 5G network plays a crucial role in ensuring its smooth operation.

Great Challenges Faced by Industrial Internet in Rapid Deployment

Fueled by the surge of digital economy in recent years, the industrial Internet has experienced rapid development. However, as the industrial Internet expands on a large scale, certain challenges have emerged in its platform construction.

- Currently, the typical application of the industrial Internet primarily revolves around simple digital transformation, lacking a unified construction solution. This "single-point" service approach may exacerbate the creation of information silos within enterprise digital transformation. Moreover, traditional enterprises' IT and OT networks are constructed by different manufacturers and managed by independent departments, resulting in internal "walls". Consequently, the digital transformation of enterprises is still in its preliminary stage.

- At present, the industrial Ethernet continues to dominate the network infrastructure in the production domain of enterprises. However, the complex wired connections pose great pressures on network deployment and flexible transformation within these enterprises.

- Most enterprises are incapable of moving to cloud at the production edge. The more complex the process and scale of intelligent manufacturing, the greater the need for data integration and exposure among various systems. However, in the core OT domain of industry, the mainstream industrial control systems are currently incompatible and lack interoperability. For enterprises, the most valuable asset is data. The current state of fragmented data makes it difficult for enterprises to accumulate digital assets, hindering process optimization and iterative improvements.

5G Empowers the Industrial Internet

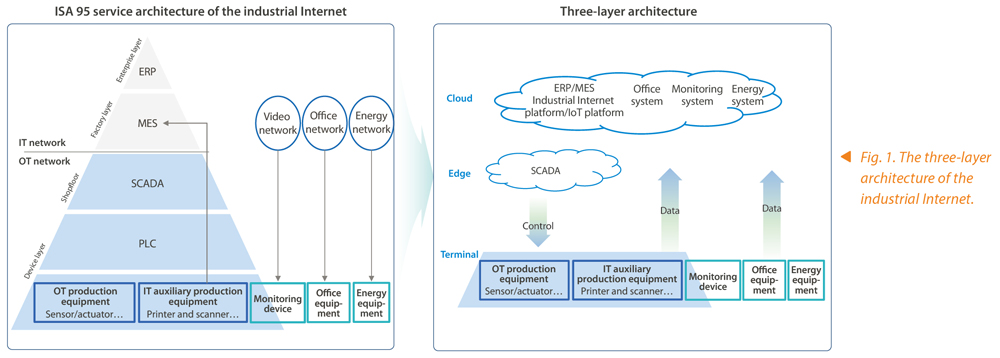

The introduction of 5G offers effective solutions to the challenges encountered by the industrial Internet. In terms of connectivity, 5G simplifies the traditional five-layer architecture of the industrial Internet into three layers (Fig. 1), facilitating the integration of data silos. Regarding networking, the new 5G network architecture provides a level of reliability and stability on par with industrial Ethernet, ensuring seamless operation in the core OT domain of industrial production. Furthermore, 5G inherently possesses cloud-edge synergy capabilities, allowing enterprises to independently deploy applications and resolve the problem of fragmented data from industrial control manufacturers.

- 5G Provides a Multi-layer Fully-Connected Network

In the network construction of traditional factories, the typical approach is to first establish a "campus network" at the factory level. This campus network serves to enable the factory's IT network and some production networks to move to clouds. It offers broad coverage and is often shared with public user networks.

As the connection field extends to the "shop-floor level" and "production-line level", the "campus network" based on the sharing mode is no longer applicable. The most important problems to be solved at the shop-floor and production-line levels are the reliable connection in the OT domain and the "field network" deployed with local computing power. Unlike the "campus network" that aims to solve all connection problems with a single network, the "field network" is customized for specific OT domain services. Therefore, there will be multiple customized "field networks" to accomodate different types of OT domain scenarios.

The 5G network provides abundant networking frameworks. For the "campus network", a networking approach compatible with the operator's network can be adopted, with UPF deployed inside the campus. For the "field network", an integrated hyper-converged networking mode can be used, and the networking is completed locally in the shopfloor or production line.

- 5G Provides Enhanced Flexibility and Reliability

Currently, there are three primary technologies used in the industry for industrial Internet communication protocols: fieldbus technology, industrial Ethernet technology, and wireless technology. Comparing the three technologies, the fieldbus technology offers higher reliability, the industrial Ethernet technology has greater transmission rates, and the wireless technology provides a more portable and flexible deployment method.

The fieldbus technology is primarily used to support data communication between field sensors and controllers, between controllers and actuators, or between controllers and various input/output control stations.

The industrial Ethernet technology complies with the TCP/IP framework and offers advantages such as simple interfaces, open protocols, high reliability, fast transmission rate and convenient interoperability.

The wireless technology, represented by 5G, offers significant advantages, including the elimination of the need for power line deployment and the ability to connect to a greater number of monitoring and control points. 5G can be combined with time sensitive networking (TSN). When TSN is deployed between controllers and field devices, 5G enables high-quality deterministic delay transmission of control signals. When TSN is deployed between controllers, 5G achieves high-precision synchronous transmission of collaborative signals. When TSN is deployed between IT networks and OT network, 5G enables the uploading of production data to information systems and the distribution of control and management information to production equipment.

- 5G Computing Network Collaboration Provides Flexible Customization of Computing Power for Fully-Connected Factories

Thanks to network exposure, 5G networks inherently have collaborative computing capabilities across cloud, edge, and terminals. While investing in the construction of a 5G network, industrial enterprises can also deploy computing power close to their production sites. The enterprises can flexibly configure the computing resources of 5G networks according to the specific needs of different scenarios such as "factory-level" and "shop-floor + production-line-level". By deploying the most suitable service systems nearby, they can minimize the delay loss caused by network detour. At the same time, the edge computing power is deployed within the enterprise campus, which falls within the domain of enterprise management. This enables unified management of computing resources and upper-layer applications in accordance with the enterprise's security policies, effectively reducing data security risks.

With the flexible computing capabilities in the industrial Internet, enterprises will have more choices for their core business in the OT domain. They are no longer limited to traditional closed system solutions offered by industrial control enterprises. Instead, they have the opportunity to embrace emerging open system solutions, continuously accumulating production data and driving ongoing optimization and efficiency improvements.

Conclusion

As one of the global leaders in 5G networks, ZTE has worked with more than 90 operators and 500 partners worldwide to drive innovation and explore a wide range of 5G applications. It has accumulated numerous successful use cases in various industries. In the era of digital transformation and the construction of 5G fully-connected factories, ZTE has always been a powerful partner for operators and industry enterprises.