5G Network Slicing: Key to Digital Transformation of Industries

Industrial Digital Transformation Scenarios

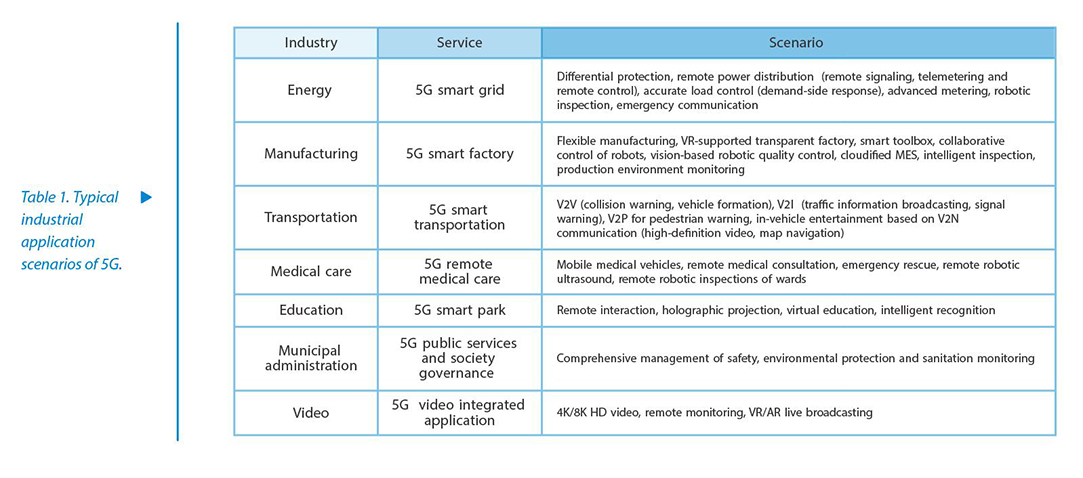

Digital transformation is the way in which enterprises apply digital technology to their production, operations or management. In the 5G era, operators are presenting exemplary applications in many different domains including medical care, transportation, manufacturing, energy, municipal administration, education, and video, driving the digital transformation of various industries through 5G technology (Table 1).

In the digital transformation of industries, different services have different requirements for latency, bandwidth, and security, and it is difficult for a single network to meet all the requirements. ZTE's 5G network slicing supports key technologies and solutions including flexible networking, slice online migration, slice capability exposure and 5G LAN/TSN. This, when combined with MEC, can meet various needs of digital transformation of different industries.

Flexible Slice Deployment Scenarios to Meet Diverse Networking Needs of Industrial Digital Transformation

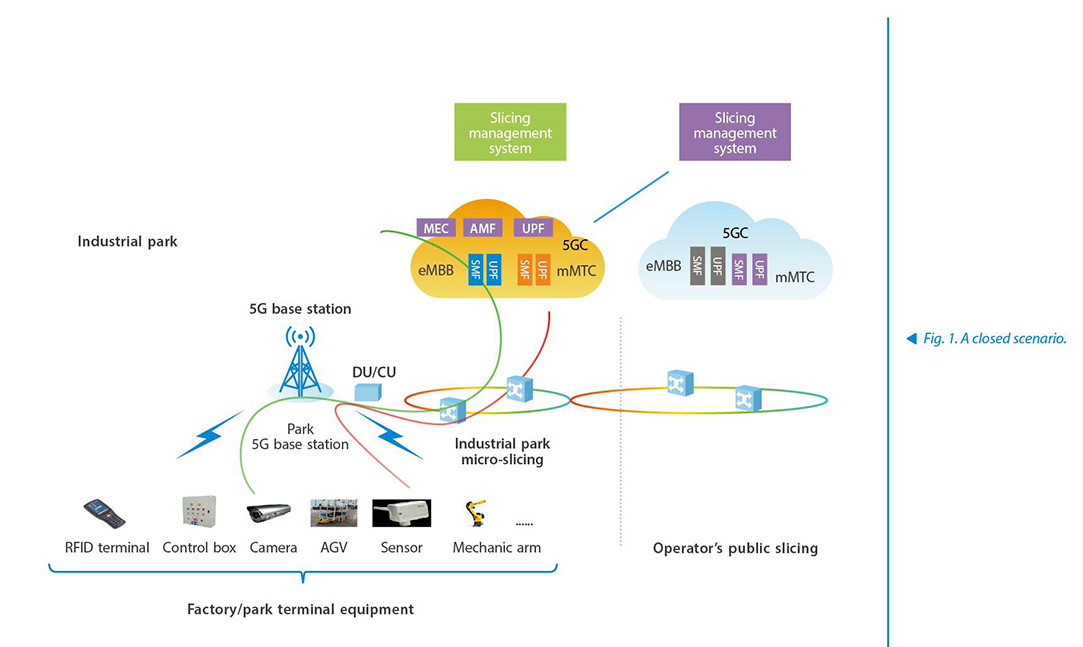

According to the coverage and security isolation requirements of different industrial applications, ZTE provides slice deployment solutions for closed scenarios, semi-closed scenarios and open scenarios. Closed scenarios include industrial parks and production workshops; open scenarios include internet of vehicles and smart grid; and semi-closed scenarios means that the same terminal may simultaneously access the internal or external slices of a park. Flexible networking is enabled by 5G slicing to cater to different scenarios.

5G LAN/TSN with Support for Point-to-Point and Point-to-Multipoint Communication in Industrial Applications

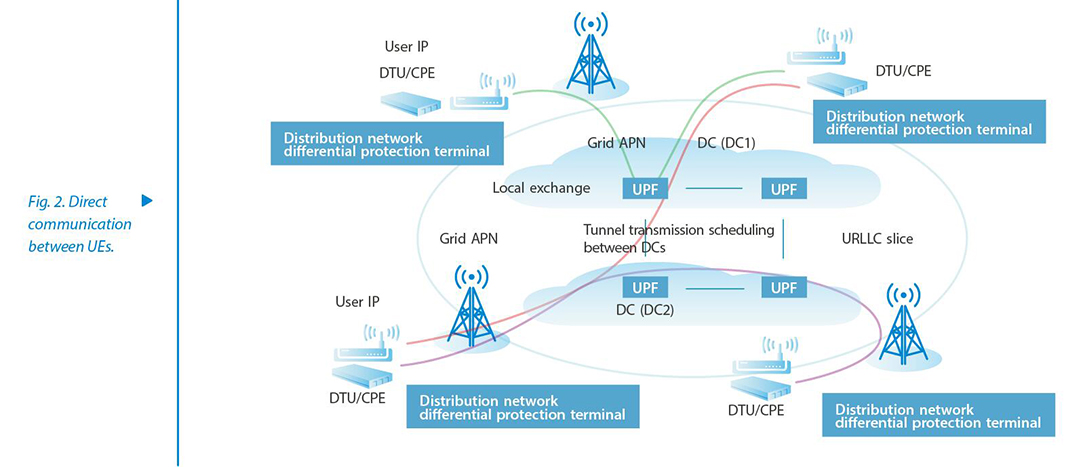

ZTE provides 5G LAN-based slices (e.g. URLLC slices for grid differential protection), which realizes UE-to-UE communication through UPF for data interaction, service unloading, and transmission latency reduction (Fig. 2). The 5G LAN terminal group management technology is provided to automatically adapt to the changing typologies of the industrial control terminals. This technology supports direct communication between service terminals in a power grid, collaboration between robots in the manufacturing industry, as well as rapid interconnection and wirelessization of devices (e.g. printers and notebook computers) in an office area.

ZTE offers a slice online migration solution that allows users to dynamically join or exit from their own slice, or migrate from one slice to another. With the slice migration technology, differentiated operations or VIP rights operations can be carried out for applications such as online games and HD theaters. The same service can run on slices of different SLA levels, for example, normal slices and high-quality slices (ultra-low latency slices or high bandwidth slices). Ordinary users can access services through normal slices by default whereas high-end industrial users can subscribe to the acceleration service online through an online mall or an industrial application portal, dynamically migrating to a higher quality slice for a better experience.

Slice Capability Exposure to Enable Visibility and Controllability of Vertical Slices

The slice capability exposure solution allows a slice to be visible, controllable and customizable, thereby supporting terminal management, QoS control of users in a slice and slice monitoring.

Terminal management refers to getting the status and location of a terminal (e.g. robot and sensor) in a slice through slice capability exposure so as to develop new services and functions such as vehicle formation management and availability detection of power grid terminals.

QoS control means modifying the QoS package of users in a slice through PFC capability exposure so as to improve the user experience. For example, for the VIP player of a game, the acceleration service can be subscribed to; and for the differential protection of the power grid, the latency policy can be modified for guaranteed reliability.

Slice monitoring allows the status of a slice to be obtained through slice capability exposure, which helps detect whether the latency and bandwidth of the actually-running slice meets the SLA requirements submitted when the slice is subscribed.

5G Slicing + MEC to Support Development of Industrial Applications

In industries like smart manufacturing, there are a large number of mass-storage and high-performance computing services such as image recognition, video analysis and VR rendering. These services are characterized by a large amount of data, which does not leave the park. MEC brings the computing closer to the user, and also supports software acceleration (DPDK) and hardware acceleration (e.g. GPU and FPGA). ZTE offers a solution that combines the high-performance computing capability of MEC with the low latency features of slices to help many industries carry out digital transformation.

VR-supported transparent factory is an example. The 5G eMBB slice + MEC solution facilitates low latency and high bandwidth communication of VR. Through local traffic offloading of slices, MEC GPU acceleration, and image rendering, the assembly process is fully digitized, thus creating a digital twin and a immersive user experience.

Unmanned aerial vehicle (UAV)-based quality inspection is another example. The drone can be used in the aircraft manufacturing industry to inspect the paint quality on the exteriors (especially the tops) of the aircraft. Videos can be transmitted back in real time. The 5G eMBB slice + MEC solution solves such problems as capturing 360-degree videos/photos, transmission, and analysis.

The Outlook

Slicing is an important digital technology in 5G that integrates advanced technologies such as cloudification/virtualization, security isolation, automation, AI, and hardware/software acceleration. With the advancement of 5G, slicing will be gradually applied to various vertical industries, promoting the development of smart manufacturing, smart grid, internet of vehicles, smart city, smart park and other domains. It will drive digital transformation across industries and aid the comprehensive development of the information society.