On May 21, ZTE partnered with Advanced Info Service Plc. (AIS), one of Thailand's top wireless carriers and Internet service providers, and Suranaree University of Technology (SUT), to demonstrate the first 5G smart factory in Thailand. Technologies involved include multiple advanced solutions such as 5G cloud machine vision, 5G industrial AGV, AR remote guidance, VR panoramic monitoring and unmanned inspection robots. The demonstration showed industrial entrepreneurs the possibility of deploying 5G in their production lines and turning their manufacturing plants into "smart factories".

AIS is the largest operator in Thailand with 47% market share. ZTE and AIS has established partnership since 2015, and ZTE became one of the key wireless solution providers that year. After the release of 5G license in 2020 by Thailand's regulator, AIS became the first operator to offer 5G service in the country. Currently, AIS 5G service has been available in major cities of all 77 provinces of Thailand.

Another partner, SUT, is located in Nakhon Ratchasima, which is the gateway to other provinces of Northeastern Thailand. The province sits at an intersection between the Eastern Economic Corridor (EEC) and the Northeastern Economic Corridor (NEEC), and it hosts three major industrial estates. Owing to this advantageous location, SUT has been serving the needs of the industrial sector with numerous curricula relating to digital technology such as AI, cloud, IoT, VR and AR. The university also offers training in the scope of 5G technology to businesses. The partnership with ZTE and AIS is expected to provide SUT with equipment that enables the demonstration of a variety of use cases for 5G. Industrial entrepreneurs would have the opportunity to exploit 5G technology for efficiency improvement at their plants by observing use cases at the university and then determining how to best implement the technology in their factories. Businesses may also discover opportunities to improve efficiency, reduce costs or increase manufacturing capacity.

The Solution

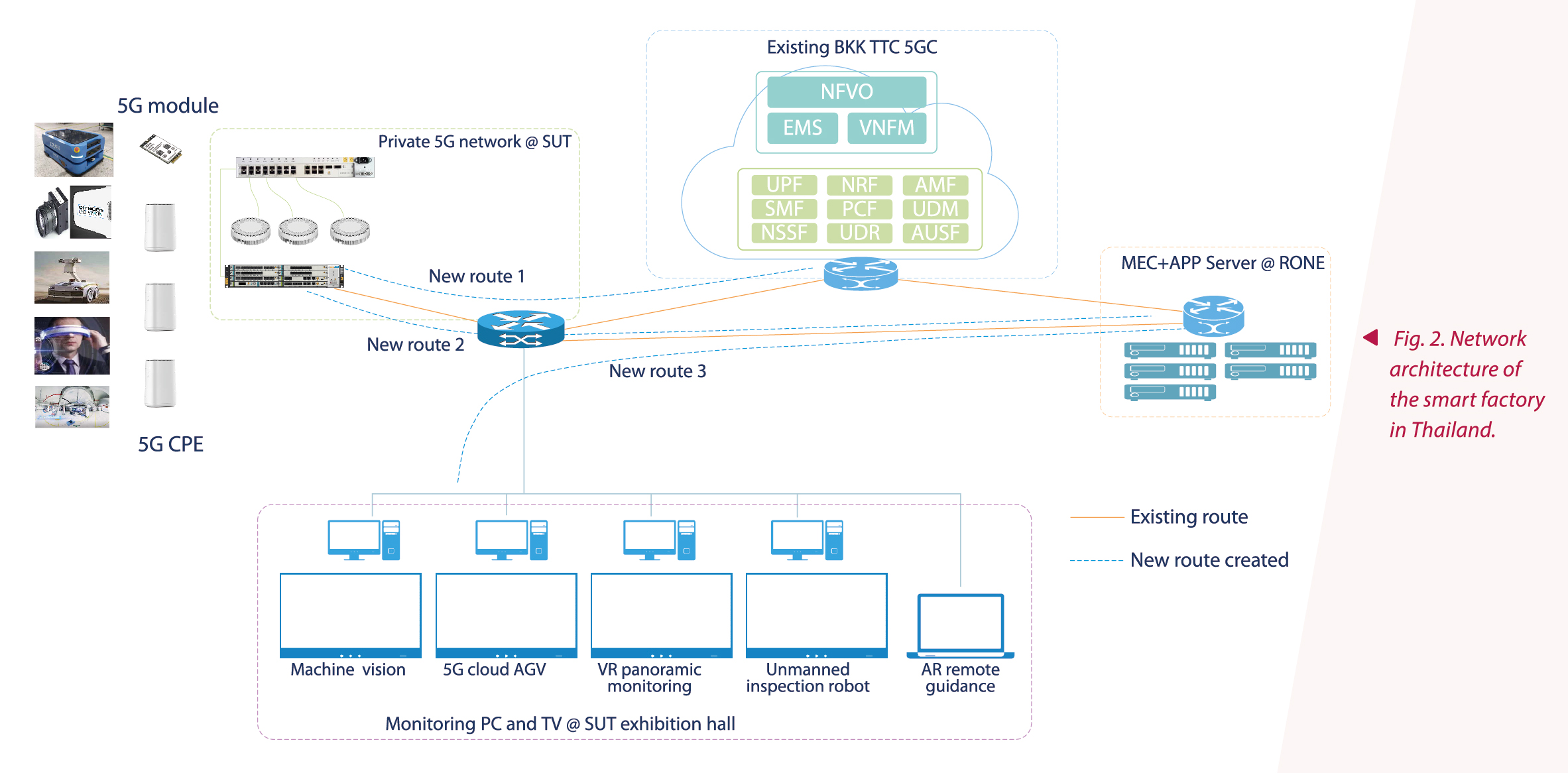

With the adoption of various new technologies (Fig. 1), the future smart factory raises much higher demands on network performance, especially the throughput and latency. The rollout of 5G and its rapid commercial maturity ensures the actual deployment of smart factory and related applications. Fig. 2 explains the overall network architecture for the smart factory in Thailand.

For the network coverage of the smart factory, ZTE QCell solution is used to provide 5G coverage at 2.6 GHz. With 40 MHz bandwidth, the 5G QCell could provide the peak throughput of 250 Mbps and 40 Mbps for downlink and uplink respectively. As the 5G network deployed is fully used to serve the network connections of the smart factory, it can be considered as a private campus network that is independent from the 5G public network of AIS. With the existing transmission path, the 5G network of the smart factory can connect with the AIS 5GC located in Bangkok. In another data center at Rone, the application servers are deployed for the smart factory. In order to further enhance the network performance for the smart factory, ZTE MEC solution is also deployed at the same data center next to the application servers. They all adopt the ZTE cloud platform. In the exhibition hall of SUT, PCs and TVs are installed to monitor and show the images fed back by applications and robots in the smart factory. Three new routes are created to ensure the links between the exhibition hall, the smart factory, 5GC and application servers.

The smart factory has perfectly integrated 5G technology with the traditional production lines. The equipment in the smart factory is connected to the 5G network through 5G CPEs or 5G modules. The 5G industrial AGV adopts LIDAR + cloud enhanced visual positioning and navigation technologies. It can rapidly and precisely plan its moving paths and operate automatically, making it a vital tool to boost efficiency inside a factory, warehouse or on a production floor.

Facial recognition-enabled 5G inspection patrol robots perform the duties of a security guard by patrolling various areas and reporting suspicious activities.

5G cloud machine vision processes the images uploaded from different working positions with the centralized machine vision station deployed at the edge cloud and displays the status and control information of the equipment on a big monitoring screen. This solution responds to the key demands of product quality control, equipment management and production line monitoring that are widely present for modern manufacturing.

5G AR remote guidance enables work, training and repair functions to be performed remotely without physical presence on site of relevant parties.

Finally, 5G VR monitoring acts as a real-time quality assurance inspection tool to ensure the application of uniform product standard from raw material to finished goods.

AIS Chief Enterprise Business Officer (CEBO) Tanapong Ittisakulchai commented, "AIS was the first to launch 5G service in February 2020, as the operator holding the most spectrum in low, medium and high bands. Over 35 billion baht budgets are allocated by AIS for year 2020 and 2021 to cover 100% of the occupied zones in the EEC and key public health centers across the country for the battle against COVID-19. With ZTE and SUT, we have jointly developed solutions to better address the needs of the industry. This smart factory demo is based on 5G Total Solutions for Industry. We have deployed 5G SA digital infrastructure on 2.6 GHz with excellent properties to support this use case, including reduced latency to provide full support for IoT."

As the solution provider for the 5G smart factory, Ling Zhi, vice president for ZTE global marketing explained, "As a major international provider of telecommunication, enterprise and consumer technology, ZTE is willing to expand 5G intelligent manufacturing in Thailand. Together with AIS and SUT, we are providing industrial customers with the innovative solution, aiming to serve the enterprises with 5G based flexible and intelligent end-to-end solutions. Committed to empowering traditional industries with 5G, ZTE has carried out innovations with partners for 5G applications across over 15 key industries. Moving forward, together with AIS and SUT, we will help Thailand's manufacturing industry to evolve towards a green, low-carbon, digital, and intelligent future."